| PIP | Title | Description |

|---|---|---|

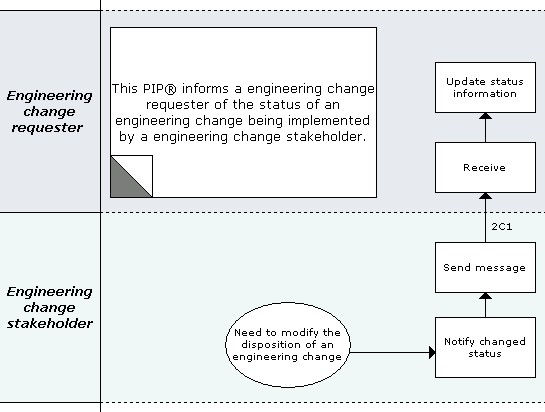

| 2C1 | Distribute Engineering Change Status | This PIP informs a engineering change requester of the status of an engineering change being implemented by a engineering change stakeholder. |

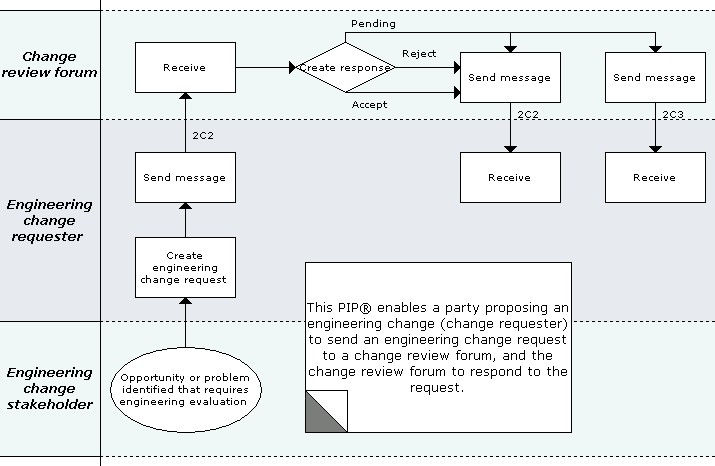

| 2C2 | Request Engineering Change | This PIP enables a party proposing an engineering change (change requester) to send an engineering change request to a change review forum, and the change review forum to respond to the request. |

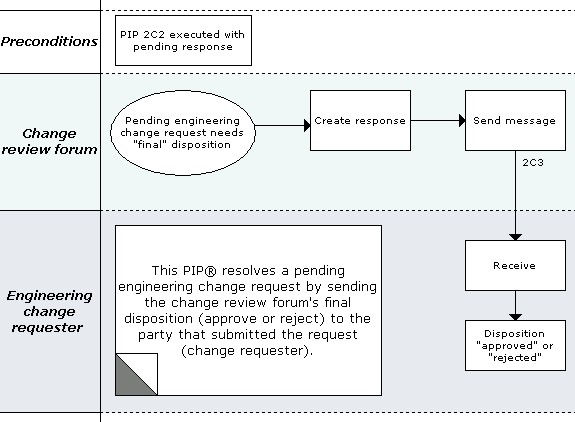

| 2C3 | Distribute Engineering Change Response | This PIP resolves a pending engineering change request by sending the change review forum's final disposition (approve or reject) to the party that submitted the request (change requester). |

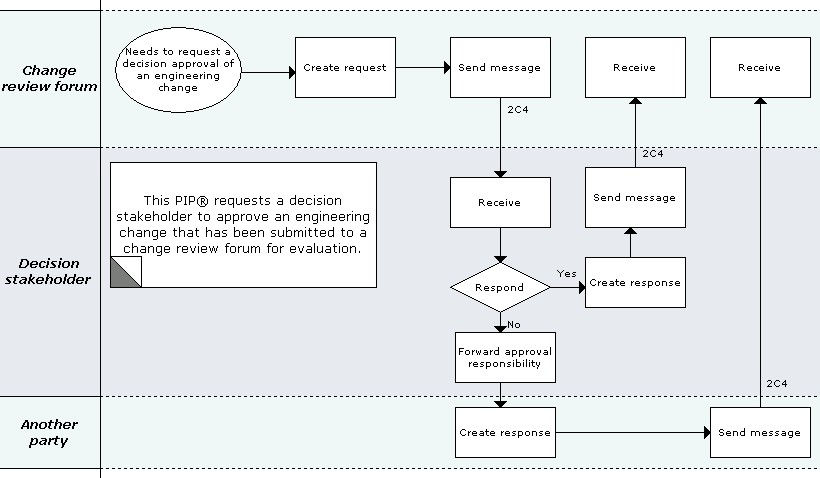

| 2C4 | Request Engineering Change Approval | This PIP requests a decision stakeholder to approve an engineering change that has been submitted to a change review forum for evaluation. |

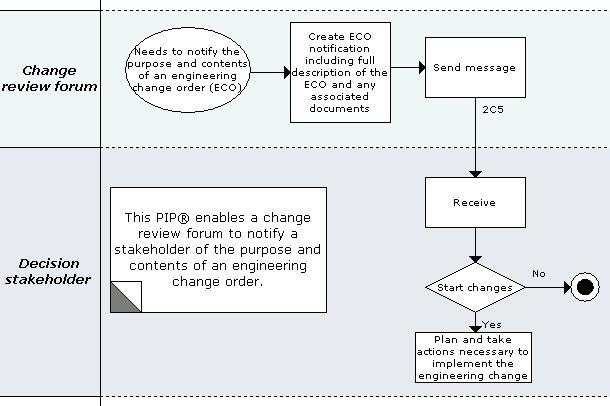

| 2C5 | Notify of Engineering Change Order | This PIP enables a change review forum to notify a stakeholder of the purpose and contents of an engineering change order. |

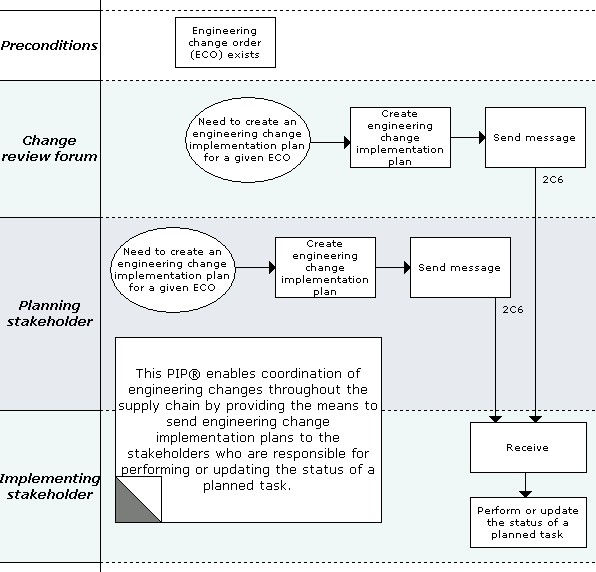

| 2C6 | Notify of Engineering Change Implementation Plan | This PIP enables coordination of engineering changes throughout the supply chain by providing the means to send engineering change implementation plans to the stakeholders who are responsible for performing or updating the status of a planned task. |

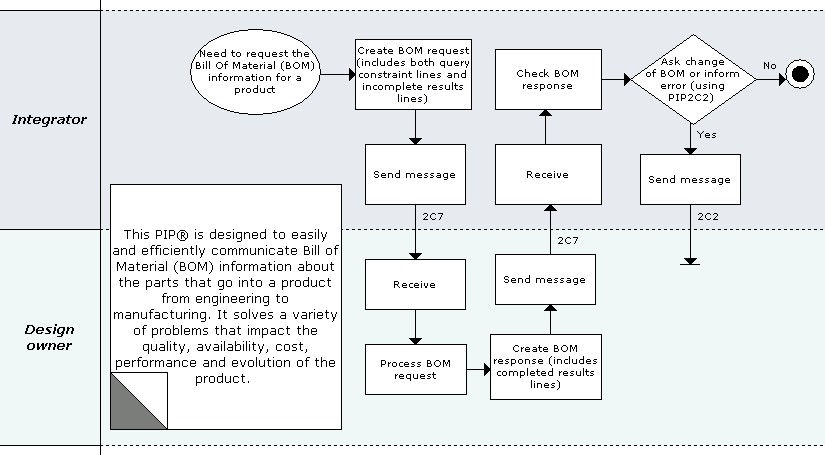

| 2C7 | Request Bill Of Material | This PIP is designed to easily and efficiently communicate BOM information about the parts that go into a product from engineering to manufacturing. It solves a variety of problems that impact the quality, availability, cost, performance and evolution of the product. Product quality is improved by reducing the occurrence of mismatched materials. Better communication of the materials required enables the manufacturer to have the parts available, improving the availability of the product. Support for regional buying, where equivalent materials need to be sourced in different regions worldwide, also enhances availability. Greater visibility of materials across multiple products allows for greater reuse and economies in purchasing. As the product evolves, changes to the BOM can be communicated efficiently. |

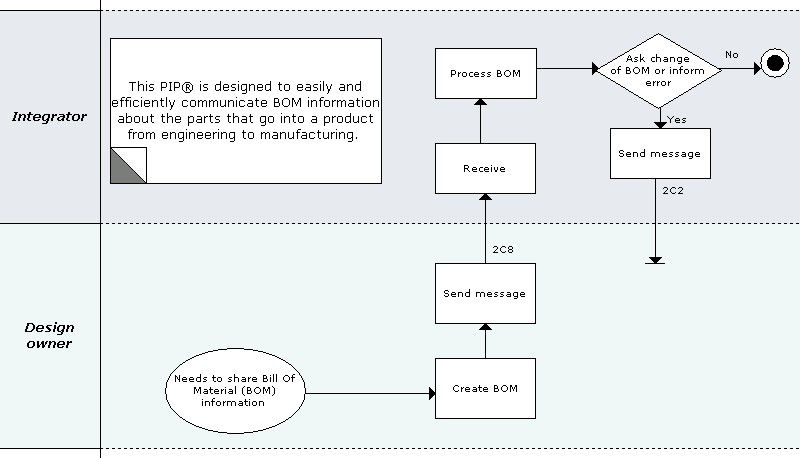

| 2C8 | Notify of Bill Of Material | This PIP is designed to easily and efficiently communicate BOM information about the parts that go into a product from engineering to manufacturing. It solves a variety of problems that impact the quality, availability, cost, performance and evolution of the product. Product quality is improved by reducing the occurrence of mismatched materials. Better communication of the materials required enables the manufacturer to have the parts available, improving the availability of the product. Support for regional buying, where equivalent materials need to be sourced in different regions worldwide, also enhances availability. Greater visibility of materials across multiple products allows for greater reuse and economies in purchasing. As the product evolves, changes to the BOM can be communicated efficiently. |

| 2C9 | Request Approved Manufacturer List | This PIP is designed to easily and efficiently communicate AML information about the parts that are approved for a product from engineering to manufacturing. It supports the exchange of mappings from internal part numbers to manufacturer part numbers, where manufacturer is loosely defined as the last partner to affect a change to the part. It also supports the mapping of these part numbers to supplier part numbers. The AML solves a variety of problems that impact quality, costing and lead times. Quality is improved by specifying precise definitions of the parts that are approved and the suppliers that are approved to supply them. The AML assists in costing and in planning lead times. The AML provides traceability into the process of part acquisition. The AML also allows the Integrator to respond whether it is able to build the product. |

| 2C10 | Notify of Approved Manufacturer List | This PIP is designed to easily and efficiently communicate AML information about the parts that are approved for a product from engineering to manufacturing. It supports the exchange of mappings from internal part numbers to manufacturer part numbers, where manufacturer is loosely defined as the last partner to affect a change to the part. It also supports the mapping of these part numbers to supplier part numbers. The AML solves a variety of problems that impact quality, costing and lead times. Quality is improved by specifying precise definitions of the parts that are approved and the suppliers that are approved to supply them. The AML assists in costing and in planning lead times. The AML provides traceability into the process of part acquisition. The AML also allows the Integrator to respond whether it is able to build the product. |

| 2C11 | Notify of Approved Manufacturer List Request | This PIP is designed to support the business process to easily and efficiently communicate AML information about the parts that are approved for a product from engineering to manufacturing. It supports the exchange of mappings from internal part numbers to manufacturer part numbers, where “manufacturer” is loosely defined as the last partner to affect a change to the part. It also supports the mapping of these part numbers to supplier part numbers. The AML solves a variety of problems that impact quality, costing and lead times. Quality is improved by specifying precise definitions of the parts that are approved and the suppliers that are approved to supply them. The AML assists in costing and in planning lead times. The AML provides traceability into the process of part acquisition. The AML also allows the Integrator to respond whether it is able to build the product. |

| 2C12 | Notify of Approved Manufacturer List Confirmation | This PIP is designed to support the business process to easily and efficiently communicate AML information about the parts that are approved for a product from engineering to manufacturing. It supports the exchange of mappings from internal part numbers to manufacturer part numbers, where “manufacturer” is loosely defined as the last partner to affect a change to the part. It also supports the mapping of these part numbers to supplier part numbers. The AML solves a variety of problems that impact quality, costing and lead times. Quality is improved by specifying precise definitions of the parts that are approved and the suppliers that are approved to supply them. The AML assists in costing and in planning lead times. The AML provides traceability into the process of part acquisition. The AML also allows the Integrator to respond whether it is able to build the product. |

Download Product Design Information specifications.

- 2C1_DistributeEngineeringChangeStatus_R01_00_00A

- 2C2_RequestEngineeringChange_R01_00_00A

- PIP2C2_R11.00.00_RequestEngineeringChange

- 2C3_DistributeEngineeringChangeResponse_R01_00_00A

- 2C4_RequestEngineeringChangeApproval_R01_00_00A

- 2C5_NotifyOfEngineeringChangeOrder_R01_00_00A

- 2C6_NotifyOfEngineeringChangeImplementationPlan_R01_00_00A

- 2C7_RequestBillOfMaterial_R01_00_00A

- PIP2C7_R11.00.00A_RequestBillOfMaterial

- 2C8_NotifyOfBillOfMaterial_R01_00_00A

- PIP2C8_R11.00.00A_BillOfMaterialNotification

- 2C9_RequestApprovedManufacturerList_R01_00_00A

- 2C9_RequestApprovedManufacturerList_V01_00_00

- PIP2C9_R11.00.00_RequestOfApprovedManufacturerList

- 2C10_NotifyOfApprovedManufacturerList_R01_00_00A

- PIP2C10_V11.00.00_NotifyOfApprovedManufacturerList

- 2C11_NotifyOfApprovedManufacturerListRequest_R01_00_00

- PIP2C11_R11.00.00_NotifyOfApprovedManufacturerListRequest

- 2C12_NotifyOfApprovedManufacturerListRequest_V01_00_00

- PIP2C12_V11.00.00_NotifyOfApprovedManufacturerListConfirmation

- Cluster 2, Product Information, enables distribution and periodic update of product and detailed design information, including product change notices and product technical specifications.

- PIPs for Segment 2C: Product Design Information, enables release and update of product engineering design information.

| 2C1 | Distribute Engineering Change Status |

|---|---|

| This PIP informs a engineering change requester of the status of an engineering change being implemented by a engineering change stakeholder. |

Business Process

The "Distribute Engineering Change Status" Partner Interface Process (PIP) enables a stakeholder to modify the disposition of an engineering change, and then notify the engineering change requester of the change in status.

A change in status can occur anywhere along the business path of the engineering change.When the engineering change status is modified, the disposition must be provided (via this PIP) within three days.

Should this transaction not complete successfully, the requesting partner executes PIP0A1, "Notification of Failure".

| 2C2 | Request Engineering Change |

|---|---|

| This PIP enables a party proposing an engineering change (change requester) to send an engineering change request to a change review forum, and the change review forum to respond to the request. |

Business Process

The "Request Engineering Change" Partner Interface Process (PIP) enables a party to submit an engineering change request and a change review forum to respond to the request. The party requesting the change (change requester) submits an engineering change request when a stakeholder identifies an opportunity or problem requiring an engineering evaluation. The change review forum responds by either accepting, rejecting, or pending the engineering change request.

If the change review forum responds, via this PIP, that the engineering request is "pending," then the change review forum must later use PIP2C3, "Distribute Engineering Change Response," to provide a final disposition (approve or reject) to the request. The final disposition must be provided within three months after completion of this PIP.

Should this transaction not complete successfully, the requesting partner executes PIP0A1, "Notification of Failure".

| 2C3 | Distribute Engineering Change Response |

|---|---|

| This PIP resolves a pending engineering change request by sending the change review forum's final disposition (approve or reject) to the party that submitted the request (change requester). |

Business Process

The "Distribute Engineering Change Response" Partner Interface Process™ (PIP®) enables an engineering change review forum to provide a "final" disposition to an engineering change request pended in PIP2C2, "Request Engineering Change".

The change review forum sends the final disposition to the party that submitted the engineering change request (change requester). The final disposition may be either “approve” or “reject".

Should this transaction not complete successfully, the requesting partner executes PIP0A1, "Notification of Failure".

| 2C4 | Request Engineering Change Approval |

|---|---|

| This PIP requests a decision stakeholder to approve an engineering change that has been submitted to a change review forum for evaluation. |

Business Process

The "Request Engineering Change Approval" Partner Interface Process (PIP) enables a change review forum to request a decision stakeholder's approval of an engineering change, and a decision stakeholder to respond to the request. A decision stakeholder is the party that holds approval responsibility for engineering changes.

This PIP can be used to obtain a response from a decision stakeholder who belongs to an organization external to the change review forum.

The decision stakeholder may respond directly to the request or forward approval responsibility to another party. Approval responsibility includes a number of possible responses: approve, reject, waiver, and other options.

It is not required that PIP2C2, "Request Engineering Change" be executed prior to using this PIP.

Should this transaction not complete successfully, the requesting partner executes PIP0A1, "Notification of Failure".

| 2C5 | Notify of Engineering Change Order |

|---|---|

| This PIP enables a change review forum to notify a stakeholder of the purpose and contents of an engineering change order. |

Business Process

The "Notify of Engineering Change Order" Partner Interface Process (PIP) enables a change review forum to notify a stakeholder of the purpose and contents of an engineering change order (ECO).

The ECO notification includes a full description of the ECO and any associated documents.Optional text and documents may either be attached to the notification or accessed through uniform resource locator (URL) links embedded in the notification.

Upon receiving ECO information from a change review forum, a stakeholder may begin to plan and take actions necessary to implement the engineering change.

Should this transaction not complete successfully, the requesting partner executes PIP0A1, "Notification of Failure".

| 2C6 | Notify of Engineering Change Implementation Plan |

|---|---|

| This PIP enables coordination of engineering changes throughout the supply chain by providing the means to send engineering change implementation plans to the stakeholders who are responsible for performing or updating the status of a planned task. |

Business Process

The "Notify Of Engineering Change Implementation Plan" Partner Interface Process™ (PIP®) enables a party responsible for planning the implementation of an engineering change to send planning information to another stakeholder who is responsible for completing or validating completion of scheduled implementation tasks.

An engineering change implementation plan is a flexible document that may be iteratively updated to organize and track the individual tasks necessary to implement an engineering change order (ECO).

Either a stakeholder or change review forum may create an engineering change implementation plan for a given ECO. Once an implementation plan is created, any stakeholder can add tasks at any time prior to the completion of all tasks in the plan.To support individual management of tasks, each task in the plan has its own owner, due date, and status.

This PIP® is usually executed when the status of the ECO associated with an engineering change implementation plan is, "Approved."

Should this transaction not complete successfully, the requesting partner executes PIP0A1, "Notification of Failure".

| 2C7 | Request Bill Of Material |

|---|---|

| This PIP is designed to easily and efficiently communicate BOM information about the parts that go into a product from engineering to manufacturing. It solves a variety of problems that impact the quality, availability, cost, performance and evolution of the product. Product quality is improved by reducing the occurrence of mismatched materials. Better communication of the materials required enables the manufacturer to have the parts available, improving the availability of the product. Support for regional buying, where equivalent materials need to be sourced in different regions worldwide, also enhances availability. Greater visibility of materials across multiple products allows for greater reuse and economies in purchasing. As the product evolves, changes to the BOM can be communicated efficiently. |

Business Process

The "Request Bill Of Material" Partner Interface Process™ (PIP®) supports a process in which

- An Integrator requests the Bill Of Material (BOM) information for a product, and

- The Design Owner for that product returns the requested information to the Integrator.

The Integrator initiates the process by sending a BOM request to the Design Owner. To facilitate communications, the request document includes both query constraint lines and incomplete results lines. After processing the request, the Design Owner completes the results lines and returns the information to the requesting party.

The Design Owner is the entity responsible for the design of the product and the Integrator is responsible for its manufacture or assembly.

The Integrator may use PIP2C2, "Request Engineering Change", to inform a Design Owner of errors in a BOM or another reason to change it.

Should this transaction not complete successfully, the requesting partner executes PIP0A1, "Notification of Failure".

| 2C8 | Notify of Bill Of Material |

|---|---|

| This PIP is designed to easily and efficiently communicate BOM information about the parts that go into a product from engineering to manufacturing. It solves a variety of problems that impact the quality, availability, cost, performance and evolution of the product. Product quality is improved by reducing the occurrence of mismatched materials. Better communication of the materials required enables the manufacturer to have the parts available, improving the availability of the product. Support for regional buying, where equivalent materials need to be sourced in different regions worldwide, also enhances availability. Greater visibility of materials across multiple products allows for greater reuse and economies in purchasing. As the product evolves, changes to the BOM can be communicated efficiently. |

Business Process

The "Notify of Bill Of Material" Partner Interface Process™ (PIP®) supports a process in which a Design Owner shares Bill Of Material (BOM) information for a product with an Integrator. The Design Owner is the entity responsible for the design of the product and the Integrator is responsible for its manufacture or assembly.

The Integrator may use PIP2C2, "Request Engineering Change", to inform a Design Owner of errors in a BOM or another reason to change it.

Should this transaction not complete successfully, the requesting partner executes PIP0A1, "Notification of Failure".

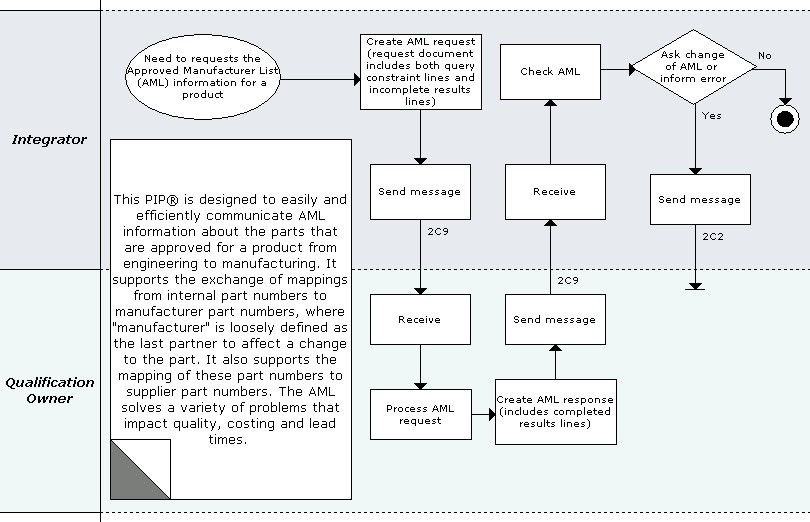

| 2C9 | Request Approved Manufacturer List |

|---|---|

| This PIP is designed to easily and efficiently communicate AML information about the parts that are approved for a product from engineering to manufacturing. It supports the exchange of mappings from internal part numbers to manufacturer part numbers, where manufacturer is loosely defined as the last partner to affect a change to the part. It also supports the mapping of these part numbers to supplier part numbers. The AML solves a variety of problems that impact quality, costing and lead times. Quality is improved by specifying precise definitions of the parts that are approved and the suppliers that are approved to supply them. The AML assists in costing and in planning lead times. The AML provides traceability into the process of part acquisition. The AML also allows the Integrator to respond whether it is able to build the product. |

Business Process

The "Request Approved Manufacturer List" Partner Interface Process™ (PIP®) supports a process in which

- An Integrator requests the Approved Manufacturer List (AML) information for a product, and

- The Qualification Owner for that product returns the requested information to the Integrator.

The Integrator initiates the process by sending an AML request to the Qualification Owner. To facilitate communications, the request document includes both query constraint lines and incomplete results lines. After processing the request, the Qualification Owner completes the results lines and returns the information to the requesting party.

The Qualification Owner is the entity responsible for qualifying parts that are approved for manufacture of the product and qualifying suppliers that are approved for acquiring these parts. The Integrator is responsible for the product's manufacture or assembly.

The Integrator may use PIP2C2, "Request Engineering Change", to inform a Qualification Owner of errors in an AML or another reason to change it.

Should this transaction not complete successfully, the requesting partner executes PIP0A1, "Notification of Failure".

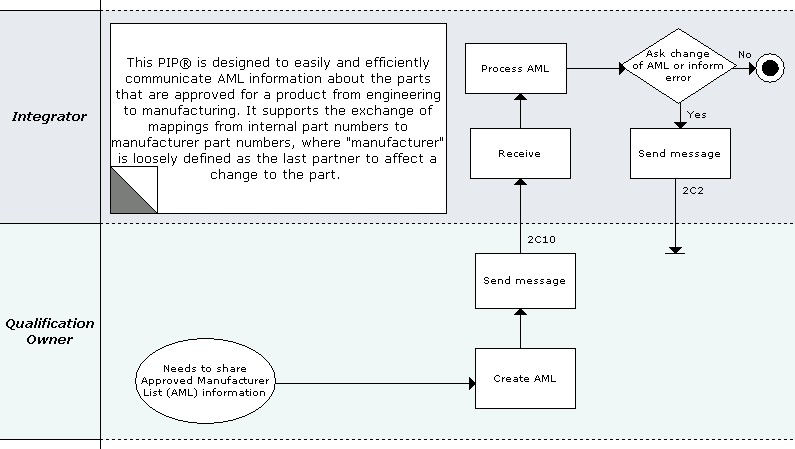

| 2C10 | Notify of Approved Manufacturer List |

|---|---|

| This PIP is designed to easily and efficiently communicate AML information about the parts that are approved for a product from engineering to manufacturing. It supports the exchange of mappings from internal part numbers to manufacturer part numbers, where manufacturer is loosely defined as the last partner to affect a change to the part. It also supports the mapping of these part numbers to supplier part numbers. The AML solves a variety of problems that impact quality, costing and lead times. Quality is improved by specifying precise definitions of the parts that are approved and the suppliers that are approved to supply them. The AML assists in costing and in planning lead times. The AML provides traceability into the process of part acquisition. The AML also allows the Integrator to respond whether it is able to build the product. |

Business Process

The "Notify of Approved Manufacturer List" Partner Interface Process™ (PIP®) supports a process in which a Qualification Owner shares an Approved Manufacturer List (AML) for a product with an Integrator. The Qualification Owner is the entity responsible for qualifying parts that are approved for manufacture of the product and qualifying suppliers that are approved for acquiring these parts. The Integrator is responsible for the product's manufacture or assembly.

The Integrator may use PIP2C2, "Request Engineering Change", to inform a Qualification Owner of errors in an AML or another reason to change it.

Should this transaction not complete successfully, the requesting partner executes PIP0A1, "Notification of Failure".

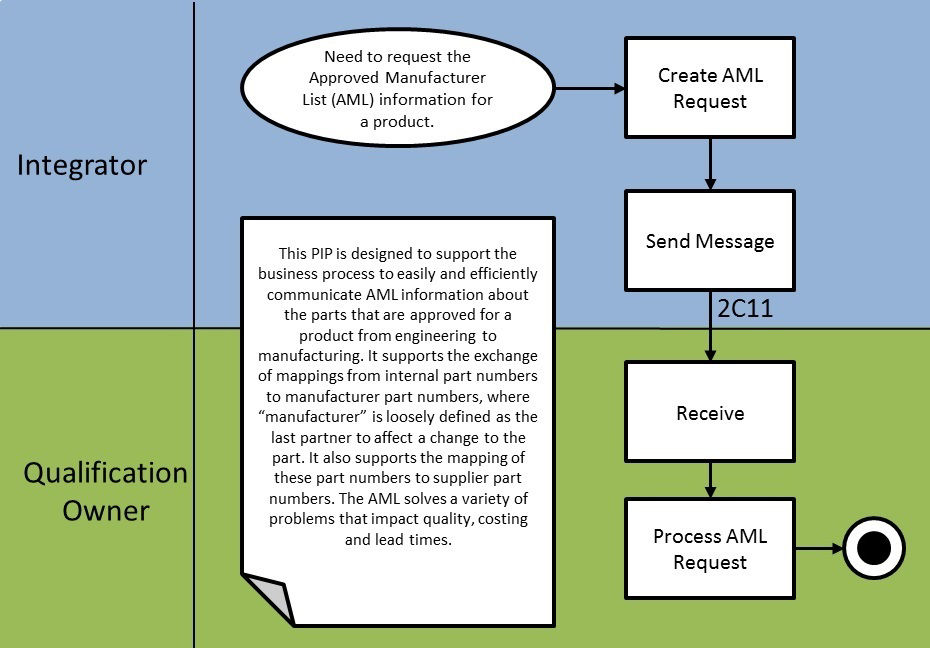

| 2C11 | Notify of Approved Manufacturer List Request |

|---|---|

| This PIP is designed to support the business process to easily and efficiently communicate AML information about the parts that are approved for a product from engineering to manufacturing. It supports the exchange of mappings from internal part numbers to manufacturer part numbers, where “manufacturer” is loosely defined as the last partner to affect a change to the part. It also supports the mapping of these part numbers to supplier part numbers. The AML solves a variety of problems that impact quality, costing and lead times. Quality is improved by specifying precise definitions of the parts that are approved and the suppliers that are approved to supply them. The AML assists in costing and in planning lead times. The AML provides traceability into the process of part acquisition. The AML also allows the Integrator to respond whether it is able to build the product. |

Business Process

The "Notify of Approved Manufacturer List Request" Partner Interface Process™ (PIP) supports a process in which an Integrator requests the Approved Manufacturer List (AML) information for a product.

The Integrator initiates the process by sending an AML request to the Qualification Owner. To facilitate communications, the request document includes both query constraint lines and incomplete results lines. After processing the request, the Qualification Owner completes the results lines and returns the information to the requesting party.

The Integrator may use PIP2C2, "Request Engineering Change", to inform a Qualification Owner of errors in an AML or another reason to change it.

Should this transaction not complete successfully, the requesting partner executes PIP0A1, "Notification of Failure."

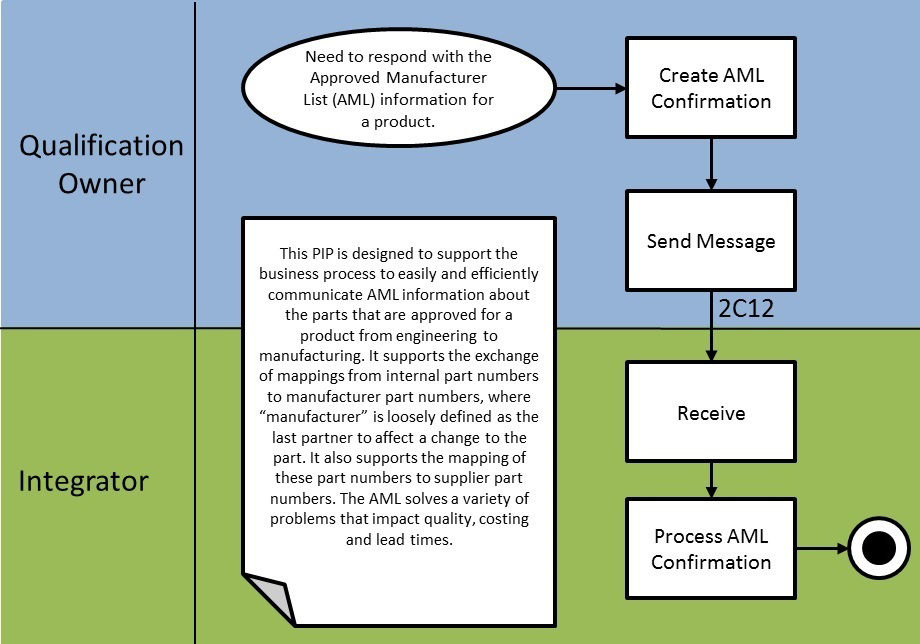

| 2C12 | Notify of Approved Manufacturer List Confirmation |

|---|---|

| This PIP is designed to support the business process to easily and efficiently communicate AML information about the parts that are approved for a product from engineering to manufacturing. It supports the exchange of mappings from internal part numbers to manufacturer part numbers, where “manufacturer” is loosely defined as the last partner to affect a change to the part. It also supports the mapping of these part numbers to supplier part numbers. The AML solves a variety of problems that impact quality, costing and lead times. Quality is improved by specifying precise definitions of the parts that are approved and the suppliers that are approved to supply them. The AML assists in costing and in planning lead times. The AML provides traceability into the process of part acquisition. The AML also allows the Integrator to respond whether it is able to build the product. |

Business Process

The "Notify of Approved Manufacturer List Confirmation" Partner Interface Process™ (PIP) supports a process in which the Qualification Owner for that product returns the requested information to the Integrator.

The Qualification Owner initiates the process and is the entity responsible for qualifying parts that are approved for manufacture of the product and qualifying suppliers that are approved for acquiring these parts. The Integrator is responsible for the product’s manufacture or assembly.

Should this transaction not complete successfully, the requesting partner executes PIP0A1, "Notification of Failure."